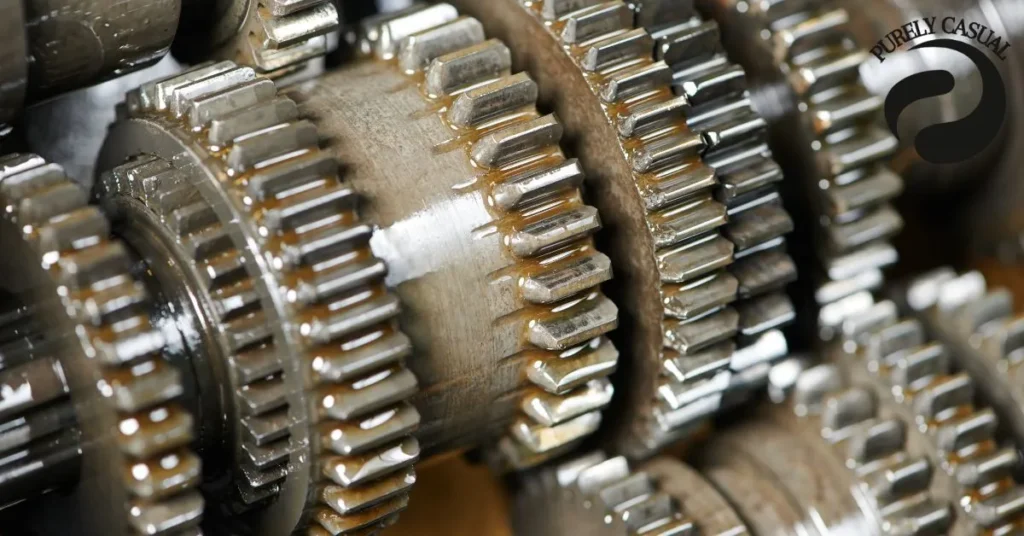

The ZF 6HP is a highly advanced automatic transmission system used in many modern vehicles. It is known for its smooth gear shifts, fuel efficiency, and performance. The solenoid system within the transmission plays a vital role in ensuring these qualities.

In the Generation 2 version of the ZF 6HP transmission, several improvements were made. These changes include upgraded solenoids and better hydraulic control. These updates make the transmission more reliable and responsive, especially in high-performance vehicles.

Solenoids are small but essential components in automatic transmissions. They regulate the flow of hydraulic fluid, which controls the gear shifts. Without them, the transmission would not function smoothly, and gear changes would be rough or delayed.

The solenoids in the ZF 6HP Generation 2 transmission manage the hydraulic pressure that operates the clutches and bands. This system allows for precise gear shifts at the right time. Understanding how these solenoids work is important for diagnosing issues or performing repairs.

This guide will focus on the solenoid diagram for the ZF 6HP Generation 2 transmission. The diagram shows how hydraulic fluid flows through the transmission, interacting with solenoids and control valves. It provides a visual overview of the hydraulic system, making it easier to understand and troubleshoot problems.

In this post, you will also learn how to use the solenoid diagram for practical purposes. Whether you are replacing a solenoid or diagnosing transmission issues, this guide will give you the knowledge to handle these tasks effectively. Understanding the solenoid diagram will also help you maintain your transmission better.

Table Of Contents

Understanding the Role of Solenoids in the ZF 6HP Transmission

What Are Solenoids and How Do They Work?

Solenoids are small electronic devices that control the flow of hydraulic fluid in automatic transmissions. They are activated by electrical signals from the transmission control module (TCM). When activated, the solenoid opens or closes a valve to allow hydraulic fluid to move through the transmission system.

In the ZF 6HP Generation 2 transmission, solenoids help manage gear shifts by controlling the hydraulic pressure. This pressure engages the clutches and bands that change gears. Without solenoids, the transmission would not be able to shift gears properly.

Also read:https://purelycasual.com/g40-1150-2jzgte-vvti-spool/

Types of Solenoids in the ZF 6HP Generation 2 Transmission

The ZF 6HP Generation 2 uses different types of solenoids to control various aspects of the transmission. The two main types are shift solenoids and pressure control solenoids. Shift solenoids control the timing of gear shifts, while pressure control solenoids manage the hydraulic pressure required for smooth operation.

There are also lock-up solenoids in the torque converter. These solenoids control the engagement of the torque converter clutch, improving fuel efficiency at higher speeds. Each solenoid has a specific function, making them vital to the overall performance of the transmission.

Importance of Solenoids in Hydraulic Control

Solenoids regulate the flow of hydraulic fluid through the valve body, which is the control center of the transmission. By controlling the hydraulic pressure, solenoids ensure smooth and timely gear shifts. If a solenoid fails, the hydraulic system may lose pressure, causing shifting issues.

In the ZF 6HP Generation 2, solenoids play a critical role in gear selection. They send hydraulic fluid to specific valves, which engage the appropriate gears. Understanding this process is essential for diagnosing transmission problems or performing repairs.

Key Solenoids in the ZF 6HP Generation 2 Transmission

There are several key solenoids in the ZF 6HP Generation 2 transmission, including shift solenoids and pressure control solenoids. These solenoids are strategically located in the valve body. The solenoid diagram can help you identify their exact positions.

Each solenoid is responsible for a different part of the transmission’s operation. For example, shift solenoids control gear changes, while pressure control solenoids ensure that the right amount of hydraulic pressure is applied. Knowing the role of each solenoid is important when troubleshooting or replacing components.

Detailed Breakdown of the ZF 6HP Generation 2 Solenoid Diagram

Explanation of the Solenoid Diagram Layout

The solenoid diagram for the ZF 6HP Generation 2 transmission is a visual guide that shows how solenoids are connected within the transmission. It includes the solenoids, control valves, and hydraulic fluid pathways. The diagram is essential for understanding how fluid moves through the transmission system and interacts with various components.

Each solenoid and valve is labeled in the diagram to make identification easier. By using this diagram, you can locate specific solenoids and understand their role in the overall system. This is helpful for troubleshooting and repairs.

Hydraulic Fluid Pathways and Connections

The hydraulic fluid pathways in the transmission are controlled by solenoids and valves. These pathways guide the movement of fluid, which is necessary for gear shifting and pressure control. The solenoid diagram illustrates how fluid flows through these pathways during normal operation.

When a solenoid is activated, it opens a valve, allowing hydraulic fluid to flow to the appropriate part of the transmission. This fluid movement engages clutches and bands, resulting in a gear change. Understanding these fluid pathways helps in diagnosing issues with shifting and pressure.

Interaction Between Solenoids and Control Valves

Solenoids work closely with control valves to manage the hydraulic system in the transmission. When a solenoid opens, it sends hydraulic fluid to a control valve, which directs the fluid to the correct gear or pressure point. This interaction is key to the smooth functioning of the transmission.

The solenoid diagram shows the exact points where solenoids and control valves interact. If a solenoid fails, the corresponding valve will not receive the correct amount of fluid, causing shifting problems. Knowing this interaction helps when troubleshooting specific gear or pressure issues.

Step-by-Step Analysis of Fluid Routing

In the ZF 6HP Generation 2 transmission, fluid routing is critical for smooth gear changes. The solenoid diagram helps visualize the fluid’s path from the pump to the clutches and bands. Each solenoid controls a part of this routing, ensuring that fluid reaches the right components.

The diagram allows you to follow the fluid as it moves through different stages of gear selection. For example, during a gear shift, fluid flows from the solenoid to the control valve and then to the clutch. This step-by-step process is vital for understanding how the transmission works.

Troubleshooting Common Diagram Issues

The solenoid diagram for the ZF 6HP Generation 2 can also help diagnose common transmission problems. If there is a shift delay or slipping, it may indicate an issue with one of the solenoids or fluid pathways. By examining the diagram, you can identify which solenoid or valve may be causing the problem.

If a solenoid is not working properly, the diagram can help you trace the fluid path to see where the failure occurred. This makes it easier to pinpoint the issue and take corrective action, such as replacing a faulty solenoid or clearing a blocked fluid pathway.

Practical Guide to Diagnosing and Replacing Solenoids

Symptoms of Solenoid Failure in ZF 6HP Generation 2

When a solenoid fails in the ZF 6HP Generation 2 transmission, you may notice several warning signs. Common symptoms include hard or delayed gear shifts, transmission slipping, or failure to shift at all. If these issues occur, the solenoid system is likely malfunctioning.

Another sign of solenoid failure is the transmission staying in a single gear, known as “limp mode.” Diagnostic trouble codes (DTCs) related to solenoid issues will also appear, which can be identified using an OBD-II scanner. These codes help pinpoint which solenoid is causing the problem.

Testing and Diagnosing Solenoid Performance

To test the solenoids in the ZF 6HP Generation 2, you will need to check the electrical resistance of each solenoid. A multimeter can be used for this purpose. If the resistance is outside the recommended range, it indicates that the solenoid is either failing or faulty.

The solenoid diagram for the ZF 6HP Generation 2 will assist in identifying the exact solenoid to test. Additionally, you can perform pressure tests to ensure hydraulic fluid is flowing correctly. If the fluid pressure is low or inconsistent, a malfunctioning solenoid may be the cause.

Using the Solenoid Diagram for Troubleshooting

The solenoid diagram for the ZF 6HP Generation 2 transmission is crucial when diagnosing transmission issues. By following the diagram, you can trace the hydraulic fluid pathways and locate the solenoid that controls a specific gear or function. This makes it easier to identify which solenoid may be causing the problem.

For example, if you’re experiencing delayed shifting, you can use the diagram to check the solenoid responsible for that gear. By following the fluid path in the diagram, you can also see if a valve or fluid blockage is contributing to the issue.

Step-by-Step Solenoid Replacement Procedure

Replacing a solenoid in the ZF 6HP Generation 2 transmission requires basic mechanical tools and attention to detail. First, disconnect the battery to prevent any electrical shock. Then, remove the transmission pan to access the valve body where the solenoids are located.

Once you have identified the faulty solenoid using the solenoid diagram for the ZF 6HP Generation 2, carefully disconnect it from the electrical connector. Remove the solenoid and replace it with a new one. Ensure that the new solenoid is properly installed, and reconnect the electrical components before reassembling the transmission.

Tools and Safety Precautions for Solenoid Replacement

When replacing solenoids, always use the correct tools, such as a multimeter, socket wrench, and a transmission jack. It’s important to follow safety precautions, including wearing gloves and ensuring the vehicle is on stable ground. Proper lighting will also help you see the components clearly.

Make sure to handle the solenoids with care, as they are sensitive electronic parts. After replacing the solenoid, check for any leaks and perform a test drive to ensure the transmission is shifting smoothly. Following these steps will help you successfully replace solenoids in your transmission.

Conclusion

The ZF 6HP Generation 2 transmission relies heavily on its solenoid system for smooth and precise gear shifts. Understanding how these solenoids work and using the solenoid diagram for the ZF 6HP Generation 2 transmission can make diagnosing and repairing issues much easier. Whether it’s identifying hydraulic fluid pathways or troubleshooting a faulty solenoid, the diagram is an invaluable tool.

By recognizing the signs of solenoid failure and knowing how to test and replace them, you can keep your transmission running smoothly. Proper maintenance, including checking fluid levels and ensuring the solenoids are functioning correctly, will extend the life of your transmission. With the right tools and knowledge, maintaining or repairing the solenoid system in your ZF 6HP Generation 2 transmission becomes a manageable task.

FAQs

What does the solenoid do in the ZF 6HP Generation 2 transmission?

The solenoid in the ZF 6HP Generation 2 transmission controls the flow of hydraulic fluid that manages gear shifts. It regulates the pressure and timing to ensure smooth transitions between gears.

What are common signs of solenoid failure in the ZF 6HP transmission?

Common signs include delayed or hard shifting, transmission slipping, and the vehicle entering “limp mode.” Additionally, diagnostic trouble codes (DTCs) related to solenoid failure may appear.

How can I test a solenoid in the ZF 6HP Generation 2 transmission?

You can test a solenoid using a multimeter to measure its electrical resistance. If the resistance is outside the recommended range, the solenoid may be faulty. Pressure testing can also be used to check hydraulic fluid flow.

Can I replace a faulty solenoid myself?

Yes, you can replace a faulty solenoid if you have basic mechanical skills and the right tools. The solenoid diagram for the ZF 6HP Generation 2 helps locate the solenoid, and you can follow the proper steps to remove and replace it.

How does the solenoid diagram help with troubleshooting?

The solenoid diagram shows the layout of solenoids, valves, and fluid pathways. It helps you trace hydraulic flow and identify which solenoid or valve may be causing a problem, making troubleshooting more efficient.

What tools do I need to replace a solenoid in the ZF 6HP transmission?

You will need a multimeter, socket wrench, transmission jack, and basic hand tools. It’s important to have safety equipment like gloves and stable lighting for the repair process.

How can I prevent solenoid failure in my ZF 6HP transmission?

Regular maintenance, such as changing the transmission fluid and checking for leaks, can help prevent solenoid failure. Keeping the transmission clean and free of debris also ensures that the solenoids function correctly.