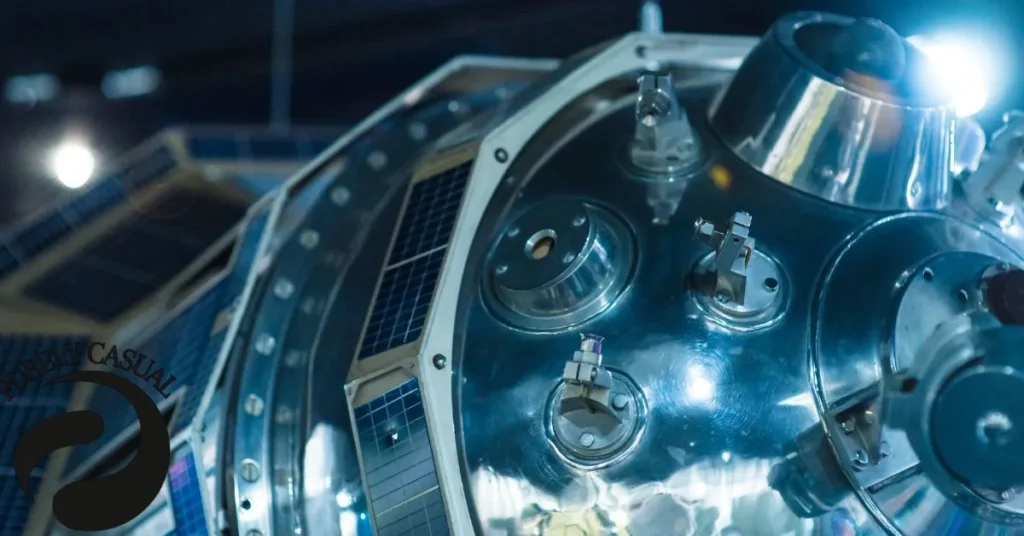

AMS39K is a cutting-edge, high-performance material designed to meet the increasing demands of modern industries. It is known for its exceptional resilience, flexibility, and durability. This material has been engineered to withstand harsh environments while maintaining its strength and integrity.

Industries like aerospace, automotive, and manufacturing are constantly searching for advanced materials to improve performance and efficiency. AMS39K is emerging as a top choice due to its ability to address the challenges these sectors face. It offers a unique combination of properties that make it suitable for a wide range of applications.

One of the standout features of AMS39K is its ability to handle extreme conditions. Whether it’s high temperatures or exposure to chemicals, this material remains stable and reliable. This makes it especially useful in industries where materials are constantly pushed to their limits, like aerospace.

The automotive industry also benefits from the flexibility and strength of AMS39K. It can be used to create lighter, more efficient components without sacrificing safety or performance. Reducing the weight of parts is critical in improving fuel efficiency and reducing emissions.

AMS39K also has applications in manufacturing and other sectors where durability is key. Products made from this material last longer, which helps reduce maintenance costs and downtime. Its versatility and reliability are quickly making it a go-to material for many industries.

In the coming years, AMS39K is expected to become a leader in high-performance materials. Its unique properties position it as a solution for the challenges of modern industrial applications.

Table Of Contents

Key Features and Properties of AMS39K

Resilience: Withstanding Harsh Conditions

The material is highly resilient, making it ideal for use in extreme environments. It can endure wear and tear while maintaining its structural integrity. This is crucial in industries like aerospace, where materials face constant stress.

Flexibility: Adapting to Dynamic Needs

Flexibility is another standout feature. It can handle changes in pressure and movement without breaking or losing its shape. This makes it perfect for the automotive industry, where components need to be both strong and adaptable.

Thermal Stability: High Performance at Extreme Temperatures

It performs well across a wide range of temperatures. It remains stable even in very hot or cold conditions, which is critical in aerospace applications. This thermal stability ensures consistent performance under extreme environmental conditions.

Chemical Resistance: Protection Against Corrosion

The material is resistant to chemicals and corrosive substances. This property allows it to be used in environments where exposure to harsh chemicals is common. Industries like manufacturing benefit from this, as it reduces the need for frequent material replacements.

Mechanical Strength: High Tensile Strength and Impact Resistance

It has high mechanical strength, which means it can bear heavy loads and resist impacts. Its tensile strength makes it durable and long-lasting. This makes it a preferred material in sectors where toughness is essential, such as defense and manufacturing.

Applications of AMS39K in Modern Industries

Aerospace: Enhancing Performance and Reducing Weight

The material is widely used in the aerospace industry because of its lightweight and durable nature. It helps reduce the weight of aircraft without compromising strength. This leads to improved fuel efficiency and better overall performance in flight.

Automotive: Creating Lighter and Safer Components

In the automotive industry, it is used to develop lighter vehicle components. These components improve fuel efficiency and reduce emissions. Additionally, its strength ensures that vehicles remain safe and durable, even with reduced weight.

Manufacturing: Increasing Durability and Reducing Costs

Manufacturers benefit from its long-lasting properties. Products made from this material have a longer lifespan, reducing the need for frequent replacements. This leads to lower maintenance costs and less downtime, making operations more efficient.

Defense and Military: Withstanding Harsh Environments

It is also used in defense and military applications due to its resilience. It can withstand extreme conditions and heavy use without losing its functionality. This makes it ideal for equipment used in harsh environments.

Medical Devices: Offering Customizable Solutions

The medical field is exploring the use of this material in various devices. Its flexibility and chemical resistance make it a suitable option for medical components. It offers the potential to create safer, long-lasting devices for healthcare applications.

The material’s wide range of applications shows its versatility in addressing the needs of modern industries. Its ability to perform well in different environments and industries makes it a valuable asset across various sectors.

Benefits of AMS39K Over Traditional Materials

Longevity: Extending Product Lifespan

This advanced material offers a much longer lifespan than traditional options. It is designed to endure harsh environments and heavy use without breaking down. This makes it a cost-effective solution, as products last longer and need fewer replacements.

Efficiency: Reducing Maintenance and Downtime

Products made from it require less maintenance. Its resilience means fewer repairs, which reduces downtime in industries like aerospace and manufacturing. This leads to improved operational efficiency and lower long-term costs.

Weight Reduction: Lighter Yet Stronger

One of the key advantages is its ability to reduce the weight of components without sacrificing strength. In industries like automotive and aerospace, lighter materials lead to better fuel efficiency and reduced emissions. Its strength ensures safety and performance even with a lighter build.

Sustainability: Promoting Eco-Friendly Practices

It supports sustainability by reducing material waste. Its long lifespan and reduced need for replacements help minimize environmental impact. Additionally, using lighter materials can help reduce energy consumption, contributing to more eco-friendly industrial practices.

Customization: Tailored to Specific Industrial Needs

The material can be customized for specific industrial applications. Its properties can be adjusted to suit the unique demands of different sectors, such as chemical resistance or flexibility. This versatility makes it an adaptable material for a variety of industrial uses.

These benefits highlight why this advanced material is becoming a preferred choice in modern industries. Its combination of longevity, efficiency, and sustainability offers advantages over traditional materials.

The Future of AMS39K: Innovations and Trends

Ongoing Research: Expanding the Capabilities

Researchers are continuously working to improve its properties. There is a focus on enhancing its strength, flexibility, and durability. These efforts aim to broaden the material’s applications across more industries.

Potential Enhancements: Improving Performance in Extreme Conditions

Future developments may make the material even more resistant to extreme temperatures and harsh environments. Innovations could lead to better thermal stability and chemical resistance. This would make it an even stronger choice for industries like aerospace and defense.

Industry Adoption: Growing Use Across Multiple Sectors

It is quickly gaining traction in industries like aerospace, automotive, and manufacturing. As more companies recognize its benefits, its use is expected to increase. The material’s ability to meet high-performance standards makes it a valuable asset for modern industries.

Collaborations and Partnerships: Driving Material Science Innovations

It is driving new collaborations between industries and research institutions. These partnerships are helping to push the boundaries of material science. Companies are working together to explore new ways to apply it in their products and systems.

Next-Generation Technologies: Exploring New Applications

The material is expected to play a key role in emerging technologies. Its potential uses in robotics, 3D printing, and advanced manufacturing are being explored. Its versatility makes it suitable for a wide range of next-generation innovations.

The future of this material looks promising as research and innovation continue to push its limits. Its growing use in cutting-edge technologies will likely expand its impact in the years to come.

Conclusion

AMS39K is paving the way for the future of high-performance materials. Its resilience, flexibility, and strength make it a standout choice for industries like aerospace, automotive, and manufacturing. As more companies adopt AMS39K, its benefits, such as improved efficiency and reduced costs, become increasingly clear.

The material’s ability to perform in extreme conditions and withstand heavy use gives it an edge over traditional materials. With ongoing research and innovations, AMS39K will continue to evolve, offering even greater performance and versatility. As industries seek advanced solutions for modern challenges, AMS39K is set to play a critical role in shaping the future of material science.

FAQs

What is AMS39K?

AMS39K is an advanced high-performance material known for its exceptional resilience, flexibility, and durability. It is designed to meet the demands of various industries, including aerospace, automotive, and manufacturing.

What are the key benefits of AMS39K?

AMS39K offers several key benefits, including extended product lifespan, reduced maintenance and downtime, weight reduction, and improved sustainability. Its customizable properties also make it suitable for a wide range of industrial applications.

How does AMS39K compare to traditional materials?

AMS39K outperforms traditional materials in terms of longevity, efficiency, and strength. It provides better performance under extreme conditions and reduces the need for frequent replacements, leading to cost savings and enhanced operational efficiency.

In which industries is AMS39K used?

AMS39K is used in a variety of industries, including aerospace, automotive, manufacturing, defense, and medical devices. Its versatility and high-performance characteristics make it ideal for applications requiring durability and strength.

What are the future prospects for AMS39K?

The future of AMS39K looks promising with ongoing research focused on enhancing its properties and expanding its applications. It is expected to play a significant role in next-generation technologies, including robotics and 3D printing.

How can AMS39K be customized for specific applications?

AMS39K can be tailored to meet the specific needs of different industries by adjusting its properties such as chemical resistance, thermal stability, and flexibility. This customization allows it to address unique challenges in various applications.

What is the impact of AMS39K on sustainability?

AMS39K contributes to sustainability by reducing material waste and energy consumption. Its long lifespan and reduced need for replacements help minimize environmental impact, making it a more eco-friendly choice compared to traditional materials.