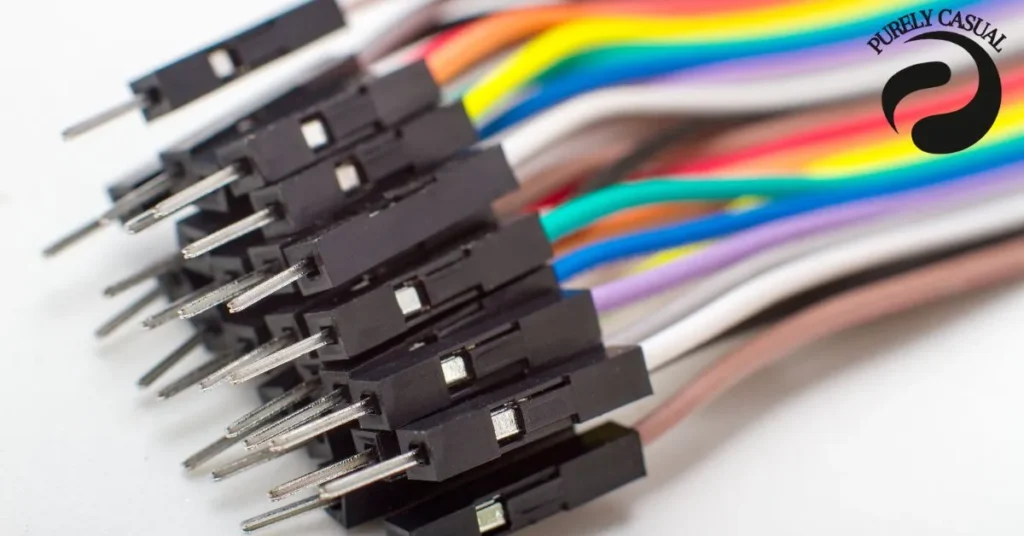

DBX1 is a well-known component series used in a variety of electronic devices. These components play a critical role in various applications, including automotive systems, industrial electronics, and consumer devices. Engineers and technicians frequently rely on DBX1 parts to ensure their circuits run smoothly.

However, there are times when using the original DBX1 component might not be possible. This can happen due to shortages, obsolescence, or the need to reduce costs. In such cases, understanding DBX1 alternatives becomes essential for anyone working with electronics.

DBX1 alternatives are substitute components that offer similar functionality to the original DBX1 parts. These substitutes are carefully selected based on factors like electrical characteristics, size, and performance. Engineers must choose these alternatives carefully to ensure they meet the same specifications and requirements as the original component.

Finding the right DBX1 alternative can save time and money, especially in large-scale projects. It can also help when original parts are difficult to find or discontinued. Using a reliable DBX1 replacement ensures that the performance and durability of the device or circuit are not compromised.

This guide aims to provide engineers and technicians with all the information they need to understand and choose the right DBX1 substitutes. It will cover when and why these alternatives are needed, how to select them, and some popular substitutes available in the market. By the end, you’ll be equipped with the knowledge to confidently replace DBX1 components in your designs.

Also read:https://purelycasual.com/capital-electric-po-box-410079-kansas-city/

Table Of Contents

Why and When You Need DBX1 Alternatives

Sometimes, engineers and technicians face challenges when working with DBX1 components. These challenges could involve sourcing issues or the need for better performance at a lower cost. In such cases, using DBX1 substitutes becomes a practical solution.

Common Scenarios for Seeking DBX1 Substitutes

There are several reasons why you might need a DBX1 alternative. One of the most common situations is when a DBX1 component becomes obsolete. Manufacturers may stop producing certain parts, making it difficult to find replacements.

Another common scenario is a component shortage. Supply chain disruptions or high demand can lead to a shortage of DBX1 parts. When this happens, engineers must look for equivalent components that can meet the same requirements.

Cost reduction is another important reason to consider DBX1 replacements. In large-scale production, switching to a more affordable component can help reduce the overall cost without sacrificing performance. Many companies seek cheaper yet reliable alternatives to DBX1 components.

How to Identify When a DBX1 Equivalent is Necessary

It’s important to recognize when a DBX1 alternative is needed. One clear sign is when a supplier no longer offers the specific DBX1 part you need. In this case, finding an alternative becomes crucial to keep the project moving forward.

Another sign is when the DBX1 component you are using does not fit within your budget. If the original part is too expensive, switching to an equivalent can help you maintain cost efficiency in your design. Additionally, if a DBX1 part is difficult to source or takes too long to arrive, an equivalent can be a faster and more convenient option.

Finally, if your design requires better performance or flexibility, exploring alternatives can provide options that better suit your needs. DBX1 substitutes can sometimes offer enhanced features, like better temperature tolerance or improved durability, making them suitable for certain applications.

How to Choose the Right DBX1 Substitute

Selecting the right DBX1 alternative is crucial for ensuring that the substitute part performs as well as the original. Several factors must be considered when choosing a replacement component. These include electrical characteristics, size, and mechanical compatibility.

Factors to Consider for DBX1 Substitutes

The first thing to look at when choosing a DBX1 replacement is its electrical characteristics. These include factors like voltage, current rating, resistance, and capacitance. The substitute component must match or closely align with the original DBX1 part to ensure the circuit works correctly.

Another important factor is the thermal and environmental constraints of the substitute. Consider the operating temperature range and environmental conditions where the component will be used. For example, a device that operates in high heat or moisture needs a component that can withstand those conditions.

You should also take into account the mechanical specifications of the DBX1 alternative. This refers to the size, packaging, and pin layout of the component. The substitute must physically fit into the design without requiring major changes to the circuit board layout.

Tools and Resources for Finding DBX1 Substitutes

There are many tools available to help you find the right DBX1 component alternative. Online databases like Mouser, Digi-Key, and Octopart allow you to search for equivalent parts by entering the specifications of the original DBX1 component. These tools provide lists of alternatives, making it easier to compare options.

Manufacturers often provide detailed datasheets that outline the specs of their components. By reviewing these datasheets, you can ensure that the equivalent matches the key parameters of the DBX1 part. Some modern tools also use AI or machine learning to help match components based on performance and availability.

These resources make it easier to find reliable alternatives and make informed decisions when selecting a DBX1 replacement part. Using the right tool can save time and ensure the component will function as intended in your design.

How to Avoid Common Pitfalls in Selecting DBX1 Equivalents

When choosing a DBX1 alternative, it is easy to overlook small differences that can lead to bigger problems. One common mistake is selecting an alternative with slightly different electrical characteristics that cause performance issues. Always double-check that the specs closely match the original DBX1 part.

Another pitfall is not considering the compatibility with existing designs. If the DBX1 substitute has a different pin layout or requires a different voltage, it may require significant changes to your design. This could increase costs and cause delays in the project.

Finally, ensure that the source of your DBX1 replacement is reliable. It is important to buy from reputable suppliers to avoid low-quality or counterfeit parts. Verifying supplier authenticity can help you avoid issues related to component failure or poor performance.

Popular DBX1 Alternatives in the Market

Several DBX1 substitutes are available that offer similar performance to the original components. Engineers and technicians can choose from a variety of replacements, depending on their needs. Understanding the options available in the market can help you find the best replacement.

Breakdown of Common DBX1 Substitutes

There are many brands and types of DBX1 component alternatives that can replace the original part. Some of the most popular include well-known brands like Panasonic, Vishay, and NXP. These companies offer reliable substitutes for various types of DBX1 components, including resistors, capacitors, and transistors.

Each DBX1 alternative has its own set of specifications. Some might offer better performance in specific areas, such as higher voltage tolerance or faster response times. Comparing these specs to the original DBX1 component can help you choose the right replacement for your design.

Using comparison charts or tables can help visualize the differences between the DBX1 component and its alternatives. This makes it easier to see which substitute best fits your project requirements.

Manufacturer Recommendations for DBX1 Replacements

Many manufacturers provide direct recommendations for DBX1 alternatives in their catalogs or datasheets. They often suggest replacements from their own product lines or from trusted partners. These recommendations are usually based on performance, availability, and compatibility.

OEM (Original Equipment Manufacturer) alternatives are often the best option because they are designed to match the original part as closely as possible. However, aftermarket DBX1 substitutes can also provide good performance at a lower cost. It’s important to weigh these options based on your specific needs.

Reading customer reviews and feedback can also help you decide which DBX1 equivalent to choose. Other engineers and technicians may share their experiences with different alternatives, providing useful insights about performance and reliability.

Sourcing DBX1 Replacements

Sourcing DBX1 substitutes can be done through a variety of suppliers, both global and regional. Online platforms like Digi-Key, Mouser, and Farnell are popular choices for finding and purchasing DBX1 equivalents. These suppliers offer a wide range of components and allow you to compare prices and availability easily.

When sourcing, it’s important to verify the authenticity of the supplier to avoid counterfeit parts. Counterfeit components can lead to device failure or poor performance, so working with trusted suppliers is essential. Checking certifications and customer reviews can help ensure you are getting genuine parts.

Price comparison is another important step when sourcing DBX1 replacements. Some alternatives may offer similar performance but at a lower cost. Comparing prices from different suppliers can help you find the best deal without sacrificing quality.

Practical Implementation of DBX1 Substitutes

Once you’ve chosen the right DBX1 alternative, the next step is implementing it into your design. Properly replacing the original component with a substitute requires careful attention to details like compatibility and performance testing. Following a step-by-step process can help ensure that the substitution is successful.

Conclusion

Understanding and selecting the right DBX1 equivalents is essential for engineers and technicians working with electronic components. Whether you need a substitute due to component shortages, cost concerns, or design flexibility, having a reliable alternative ensures your project stays on track.

By carefully evaluating the electrical, thermal, and mechanical properties of potential DBX1 substitutes, you can choose the best replacement for your design. Using tools and resources like online databases and manufacturer datasheets can help make this process easier and more accurate.

Finally, real-world case studies and future trends show that DBX1 replacement parts offer both immediate and long-term benefits. Staying informed about new developments in the field can help you optimize your designs and ensure the success of your projects. With the right knowledge, finding the perfect DBX1 equivalent becomes a straightforward and beneficial process.

FAQs

What are DBX1 equivalents?

DBX1 equivalents are substitute components that offer similar functionality and specifications to the original DBX1 parts. They are used when the original components are unavailable, obsolete, or when a more cost-effective solution is needed.

Why do I need to find a DBX1 equivalent?

You may need to find a DBX1 equivalent if the original part is discontinued, in short supply, or too expensive. Additionally, if your project requires improved performance or specific features, using a substitute can be beneficial.

How do I choose the right DBX1 equivalent?

When selecting a DBX1 equivalent, consider the electrical characteristics (voltage, current, resistance), thermal constraints (operating temperature), and mechanical specifications (size and pin layout). Make sure the substitute matches the original part closely to ensure proper functionality.

Where can I find DBX1 substitutes?

You can find DBX1 substitutes through online electronics suppliers such as Digi-Key, Mouser, and Farnell. These platforms provide detailed specifications and comparisons to help you choose the right equivalent.

Are DBX1 equivalents reliable?

Many DBX1 equivalents from reputable manufacturers are reliable and perform similarly to the original components. Always check customer reviews and manufacturer specifications to ensure you are selecting a high-quality substitute.

How do I implement a DBX1 equivalent in my circuit?

To implement a DBX1 equivalent, carefully remove the original component, install the substitute in the same position, and ensure proper connections. After installation, power on the circuit and test its performance to confirm that the equivalent functions correctly.

What should I do if my DBX1 equivalent doesn’t perform as expected?

If your DBX1 equivalent doesn’t perform as expected, double-check the specifications and ensure that the substitute closely matches the original part. If there are significant differences, consider finding another equivalent or consulting the manufacturer’s datasheet for troubleshooting tips.

Can I use multiple DBX1 equivalents in one project?

Yes, you can use multiple DBX1 equivalents in one project as long as each substitute meets the necessary specifications for its specific application. Make sure to evaluate each component individually to ensure compatibility within the overall design.